IFD-10

The IFD range of flow divider/combiner valves gives division of input flow into two equal parts and re-combination of flow in the reverse direction.

Pressure compensation ensures that whether dividing or combining, equal flow is maintained over a wide range of pressure variation.

A typical use of these valves is to divide a pump flow to operate two actuators (which may be under different load conditions and at different pressures) and to re-combine the return flow to synchronize system movement.

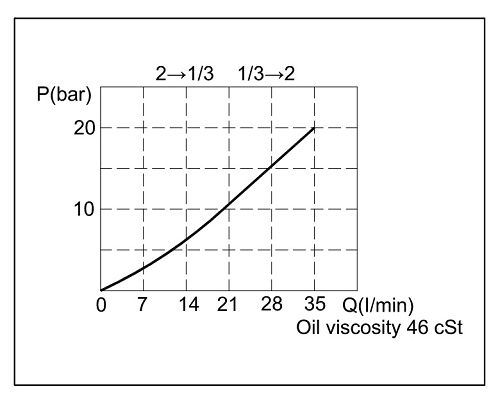

Flow variation is within +/- 10% with the maximum variations of pressure and inlet flow and under normal conditions will be significantly less.

Inlet flow (port 2) passes through the two matched orifices in the spool.

Excess flow in either direction (port 1 or port 3) causes the spool to move and close the radial holes in the sleeve until equilibrium is restored.

In the reverse direction (re-combine of port 1 or port 3 to port 2) the spool close together and regulate the flow in through the radial ports.

Rated Flow :

20 - 40 l/min

Max. pressure :

210 bar

Standard division rate :

50% ÷ 50%

Maximum division error :

± 5% of the oil flow in port 1 or port 3 and 120 bar pressure difference between port 1 and port 3. ( Division rate: 50% ÷ 50%).

Working temperature :

Min. -20℃ , Max. 90℃ , with standard BUNAN gaskets

Min. -20℃ , Max. 120℃ , with optional VITON gaskets on request

Fluid :

best use mineral oil with viscosity ranging between 10 and 200 cSt

Filter :

25 micron or better

Cavities :

see cavity data 10-04

Installation :

before screwing the cartridge on the valve body, ascertain to provide suitable gasket lubrication with clean oil and also be sure to screw the cartridge manually in to reach against the gaskets in the valve body.

.jpg)

.jpg)